Wesco HQ

9831 S. 51st Street C-119 Phoenix, AZ 85044

9831 S. 51st Street C-119 Phoenix, AZ 85044

Focused on delivering unparalleled

customer experience

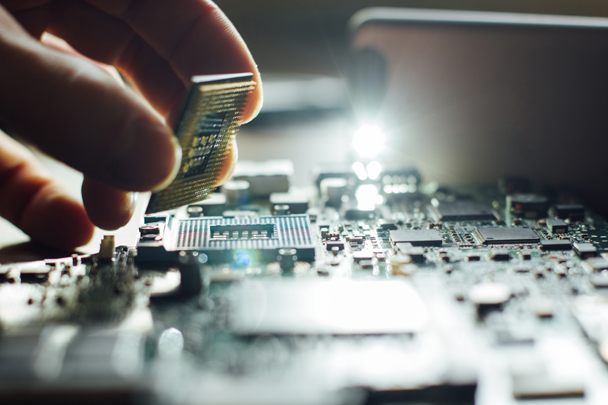

Wesco offers contract manufacturing and assembly for a wide range of manufactured electronics devices and components from simple prototype development to volume production runs.

Prototype to Production

Wesco offers Design For Manufacturability (DFM) throughout the prototype process. Our engineers work in concert with OEMs to provide a reliable printed circuit board assembly or box build solution. We can often provide quick turn assemblies withing 72 hours of last component received in stock.

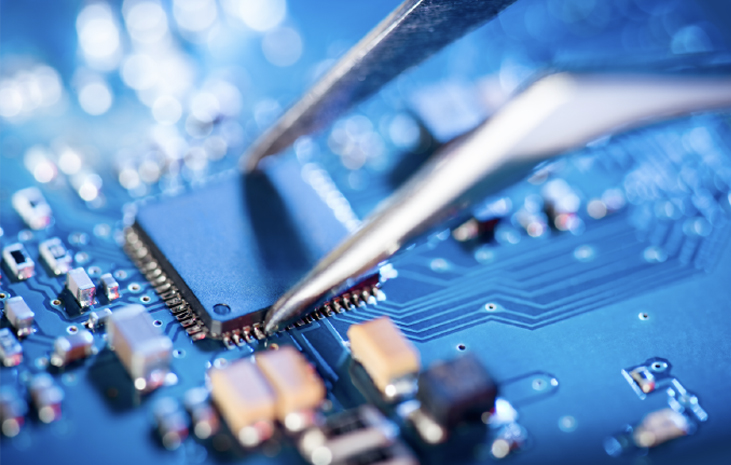

Consignment or Turnkey Manufacturing

Wesco offers consigned inventory and turnkey manufacturing solutions. As part of our Vendor Managed Inventory services, customers can provide kitted materials for work orders. Ninety percent of the time Wesco provides end to end turnkey solutions and manages inventory for its customers. Wesco will negotiate excess materials throughout the quoting and production process.

Custom Stocking Programs

Wesco will maintain an agreed amount of Finished Goods Inventory to reduce volatile production schedules. We understand our customers may have spikes or lulls in demand and we work with you to mitigate risk.

Project Management and Reporting

Wesco provides ongoing program and project management to its customers. Our account managers will facilitate your production projects from inquiry through production. With over 30 years combined electronic manufacturing services experience, we are here to support your supply chain success.